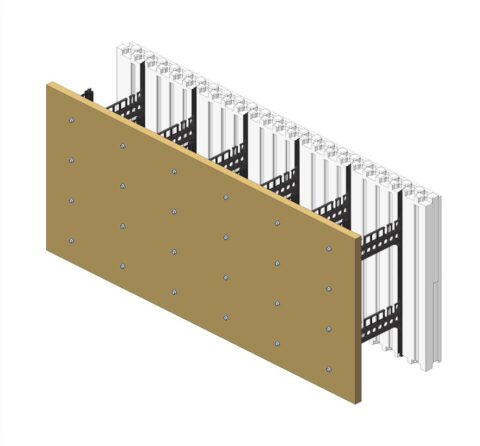

Wall formwork

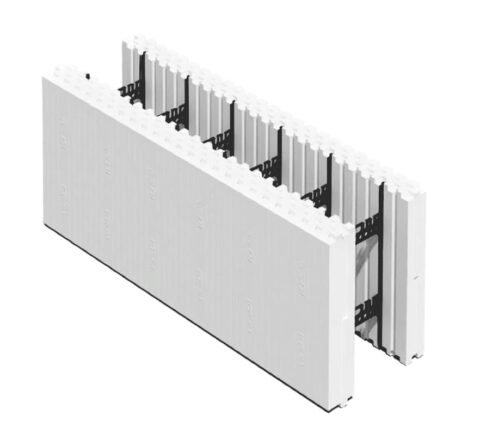

ICF Italia is a construction system using expanded polystyrene (EPS) formworks to create load-bearing reinforced concrete walls for earthquake-resistant buildings, with low energy consumption, eco-sustainability, and high acoustic insulation.

The formwork is available both with a straight development (coupling of straight panels) and with a right-angle development (Kit Corner).

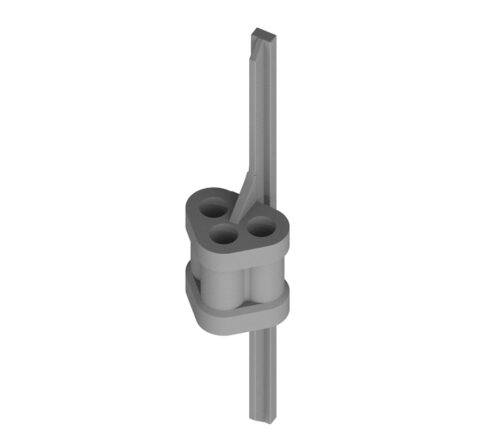

The high-density EPS components are interconnected by inserting spacers during installation, which determine the thickness of the reinforced concrete wall according to the structural project specifications.

Elements

Characteristics

The ICF Italia panels, with their innovative features, allow for increasing building quality, reducing construction costs, and minimizing time, while complying with all current regulations.

Increase building quality

They have been developed to ensure maximum thermo-hygrometric comfort in both summer and winter. In particular, they offer high thermal insulation power, and the homogeneity of materials and the “calibration” of their thicknesses guarantee the absence of thermal bridges, even at wall intersections. Dynamic parameters for summer performance have been determined, and the absence of interstitial or surface condensation has been verified.

Reduce production costs

The ICF system consists of a “standard module” with which it is possible to solve all execution problems, without special element pieces. Corner elements are also available, which are useful in particular applications. The panels are of the decoupled type, meaning they can be assembled on-site, allowing for minimizing space requirements and therefore the impact of transport.

Minimize waste

The vertical dimension of the panels has been determined based on careful evaluations related to standard building heights (floor-to-floor height and position of openings), therefore under normal conditions there is no waste. Furthermore, the panels have a minimum interlocking modularity of 25mm and can be quickly and precisely cut even in the longitudinal direction.

Speed up execution operations

The larger dimensions of the ICF ITALIA panel compared to those of systems normally available on the market and its internal structure, characterized by a double “spacer”, make installation much faster, and the insertion of reinforcements is comfortable and precise. All finishing applications are facilitated by the panel’s predispositions, such as the specially shaped external surface to improve the adhesion of cement mortars or skimming.

Comply with current regulations

The geometry of the “spacers” allows full compliance with concrete cover, spacing between bars, and distance between reinforcement bars, as required by technical construction standards and Eurocodes. The spacer also ensures the final placement of reinforcements without the need for additional on-site tying, with the possibility of also reinforcing the “critical zones” of the wall, with stirrup spacing of 10cm.

Reduce risks for workers

Safety regulations in construction sites have introduced important requirements aimed at reducing risks associated with building activities during the construction and maintenance phases of works. The ICF Italia system, by reducing the number and duration of work phases, as well as simplifying them, minimizes risks for workers.

Build better, faster, and safer. Improving efficiency, quality, and safety.

Designed with professionals in mind, it offers an optimal solution that perfectly adapts to the needs of every designer. If you are looking for a methodology that can simplify your work and guarantee excellent results, our system is the right choice.

Send us your project for a personalized consultation and discover firsthand how our system can make a difference in your work.

Construction site

The ICF Italia formwork system allows halving the construction time of buildings, resulting in a significant economic advantage for the builder. With ICF Italia, implementation becomes an activity accessible to all. Our system is designed to be intuitive and easy to install, eliminating the need for highly specialized personnel. The modules assemble quickly and without complications, allowing for an efficient and smooth workflow.

The company also offers technical assistance both in the design and execution phases: our team of engineers is able to support external technicians in designing structures, optimizing wall thicknesses and reinforcement quantities in relation to various cases.

Similarly, for construction site aspects, we have specialized workers who are able to provide assistance (start-up) to companies using our construction system for the first time.

The assembly of panels involves inserting the internal connector elements into the guides and, row by row, placing the horizontal reinforcement iron, which must be arranged in a “staggered” manner in the appropriate seats provided in the spacers, in order to create a slot for the passage of vertical irons that will be installed later.

We accompany you in

all phases of your project