PANEL PROCESSING

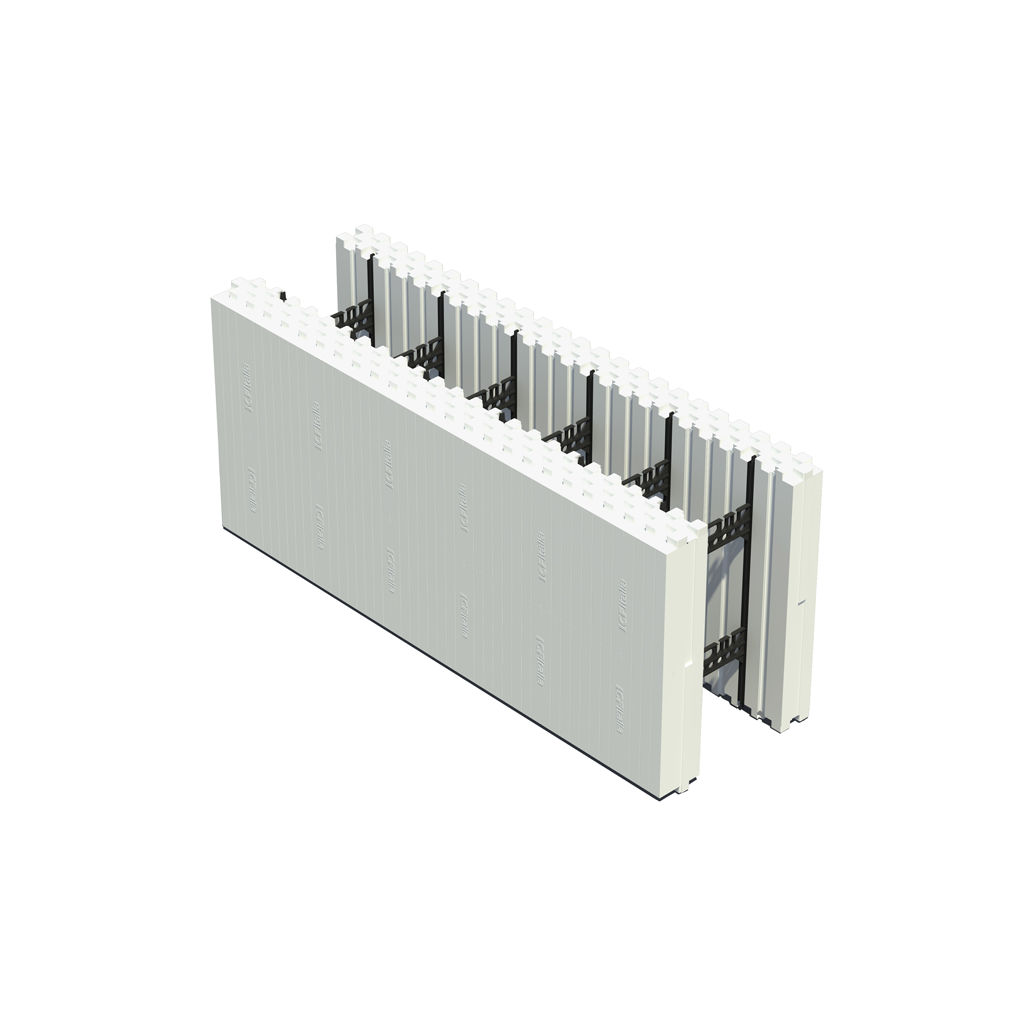

ICF ITALIA panels arrive at the construction site on special pallets, divided by type of thickness and organized in various configurations (straight panels, corner panels, any special parts).

The installation begins by choosing a wall (possibly the most linear) and positioning the first panels at the two opposite corners that delimit it. The corners can be made using special parts or straight panels, they can be easily composed.

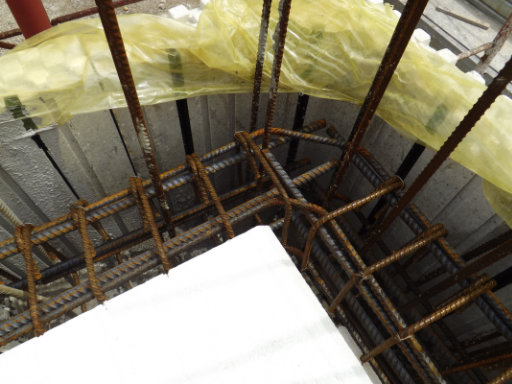

The assembly of the panels is done by inserting the internal connecting elements in the guides and, row by row, placing the horizontal reinforcement bars, which must be arranged in a “staggered” way in the special seats provided in the spacers, in order to create a slot for the passage of the vertical barss that will be installed later.

At the end of the second row (the maximum is three rows) it is appropriate to check accurately the flatness, verticality and horizontality of the panels laid, immediately making any corrections. It is therefore appropriate to start installing the specific “props” for the perpendicularity and fixing of the walls. The cuts are made easily with circular saws, bandsaws or with a cutter, following the special cutting lines pre-marked on the surface of the panels.

STRUCTURES

Once the previous assembly operations have been completed and their correct execution has been verified, you can proceed with the installation of the vertical reinforcements (which are lowered from above) and with the casting, which will be performed by pumping the concrete. Usually, for 15-20cm thick walls with medium reinforcement, S4 slump and aggregate concrete with a grain size of less than 20mm are used, casting from the central area of the wall and moving the pump along the perimeter of the building so that the concrete is arranged for “layers” of a height not exceeding 60-80cm.

ROUGH CONSTRUCTIONS

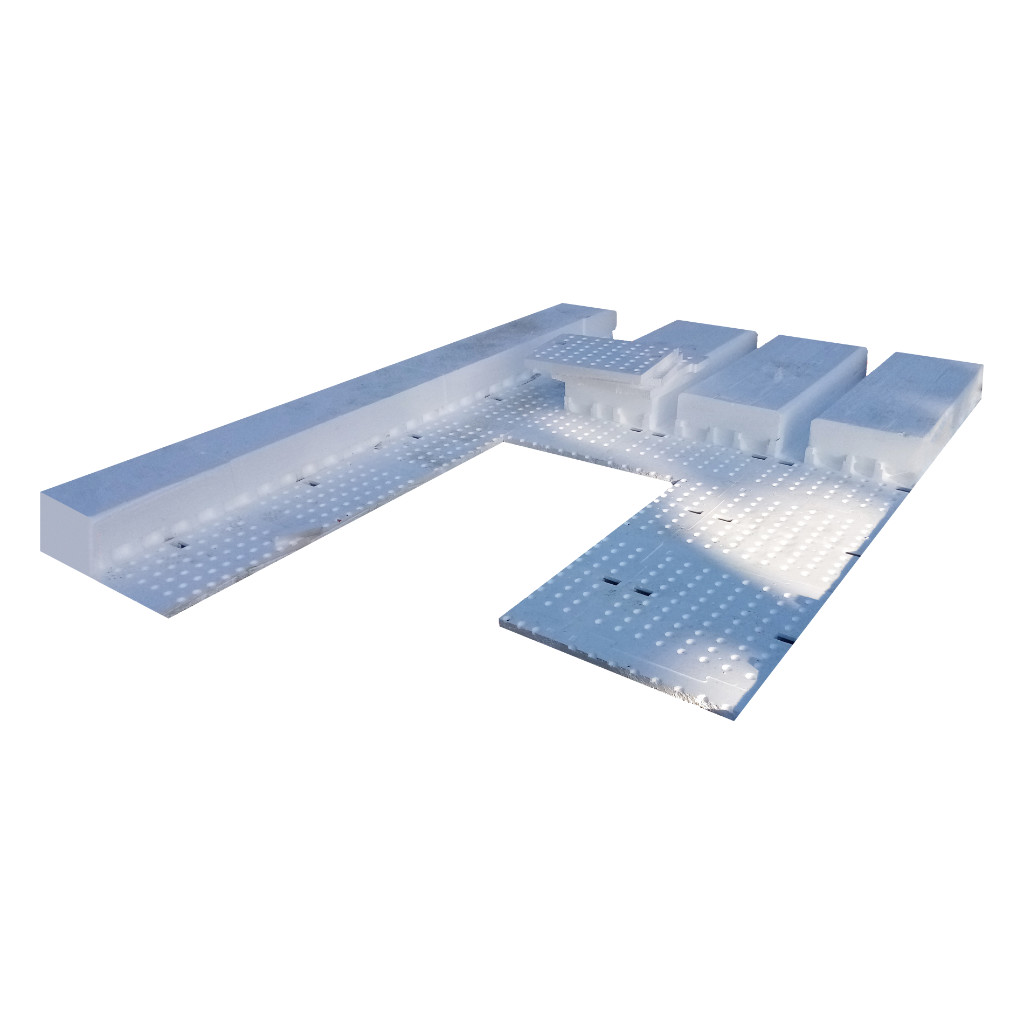

ICF ITALIA buildings in their unfinished state look as shown in the following figures, with surfaces completely covered with polystyrene and therefore free from any discontinuity or thermal bridges. There are also specific elements incorporated in the panels (both walls and floors) for fixing the finishing slabs, which are laid after the plants have been prepared.

ICF INTERACTION WITH OTHER SYSTEMS

The walls made with ICF panels can easily interact with structures made of wood (intended both as floors and as real portions of the building), steel, traditional reinforced concrete or with prefabricated buildings. The versatility of ICF system allows to create the most varied ways of anchoring wooden beams or connecting to other structural elements. Various standardized operating details are available in this regard, partially available in the download section.

FINISHES

Inside, although it is also possible to use cementitious finishes, it is highly recommended to operate using dry systems (gypsum or plasterboard plates) that allow, quickly and with low costs, to finish the job, also increasing the thermal and acoustic performance of the shell. In fact, it should be noted that ICFITALIA system allows the application of dry finishes without the need to create the so-called “substructures”, having specific predispositions inside (well highlighted on the surface) for screwing the sheets. Alternatively, the sheets can be glued onto the polystyrene.

The types of finishes possible on the external side of the walls are the same as in other exterior insulation systems, therefore an ICF ITALIA building, once finished, is indistinguishable from a traditional one.